Special ATEX Flange-Mounted Immersion Heaters

Special ATEX-compliant flanged immersion heaters are essential equipment for heating fluids, air, or gases.

They are used in industrial machines and process installations, or mounted on tanks and vessels.

Electro-Therm offers customized flanged immersion heaters tailored to each customer’s specific requirements.

Designed and manufactured with a high-quality industrial construction, or in an explosion-proof version compliant with ATEX standards, our immersion heaters ensure maximum reliability, optimal safety, and long service life for your installations.

For any specific requirements, please contact us.

Electro-Therm offers ATEX-compliant flanged immersion heaters designed for heating fluids or gases in hazardous areas.

They are available in categories GII 2G, 3G, 2D or 3D (Zones 1, 2, 21 or 22), with ATEX, GOST, IECEx and other international certifications.

ATEX flanged immersion heaters are designed according to the protection types “flameproof enclosure” (Ex d) and “increased safety” (Ex e), with IP66 protection.

Flanged immersion heaters for fluids or gases can be supplied with a complete certification package for the required temperature class, depending on local and operational conditions.

For safe and reliable temperature monitoring, immersion heaters must be equipped with an appropriate protection and control system.

Terminal enclosure of the immersion heater (Ex e – increased safety)

Materials

Material selection depends on customer requirements, the fluid being heated, and ambient conditions.

Heating element sheath:

- Stainless steel 321, 316Ti, 316L, Incoloy

- Or according to customer specifications

Flange connection:

- Carbon steel

- Stainless steel 321 or 316

- Or according to customer requirements

Connection enclosure (Ex):

- Cast iron or carbon steel with industrial-grade protective coating

- Or stainless steel 316 for demanding environments

Pressure-rated version

Pressure-rated immersion heaters are designed, manufactured, and inspected in accordance with the Pressure Equipment Code, including the Pressure Equipment Directive (PED), ASME VIII, and other international codes.

The PED category must be selected by the customer based on the conformity assessment requirements.

Specific Surface Load

The specific surface load is a measure of heat transfer to the heated medium. It must be selected based on fluid flow rate, pressure, installation conditions, fluid temperature, and permissible surface temperatures.

With a process-optimized surface load, high thermal efficiency can be achieved.

Typical values

- Crude oil, gearbox oil, bitumen: 0.8…1.0 W/cm²

- Hydraulic oil, thermal oil: 1.5…2.3 W/cm²

- Water/propylene glycol: 2…4 W/cm²

- Circulating gas: 0.5…3 W/cm²

- Motor anti-condensation heating: 0.25…0.4 W/cm²

“DHF” Type Immersion Heater

The immersion heaters can be fully certified, including temperature class certification, depending on local and operational conditions.

Ex-Marking:

GII 2 G Ex d or de IIC T1 … T6

EC-Type Examination Certificate: PTB 08 ATEX 1017 X

Applications:

Lubrication oil heaters, tank heaters, process heaters.

A level control system is required to protect the immersion heater and ensure sufficient liquid coverage over the entire heating bundle.

Typical application:

Lubrication oil heater with integrated level switch inside a compressor.

“DHG” Type Immersion Heater

“DHG” type immersion heaters are designed for heating air or gas, either in stagnant conditions or under circulation.

The temperature class is certified according to ATEX zoning and local operating conditions.

Ex-Marking:GII 2 G Ex d or de IIC T1 … T4

EC-Type Examination Certificate: PTB 08 ATEX 1040 X

Similar models (Type DHG 11 B./M-.) are designed for heating hot boxes, technical rooms, and similar applications.

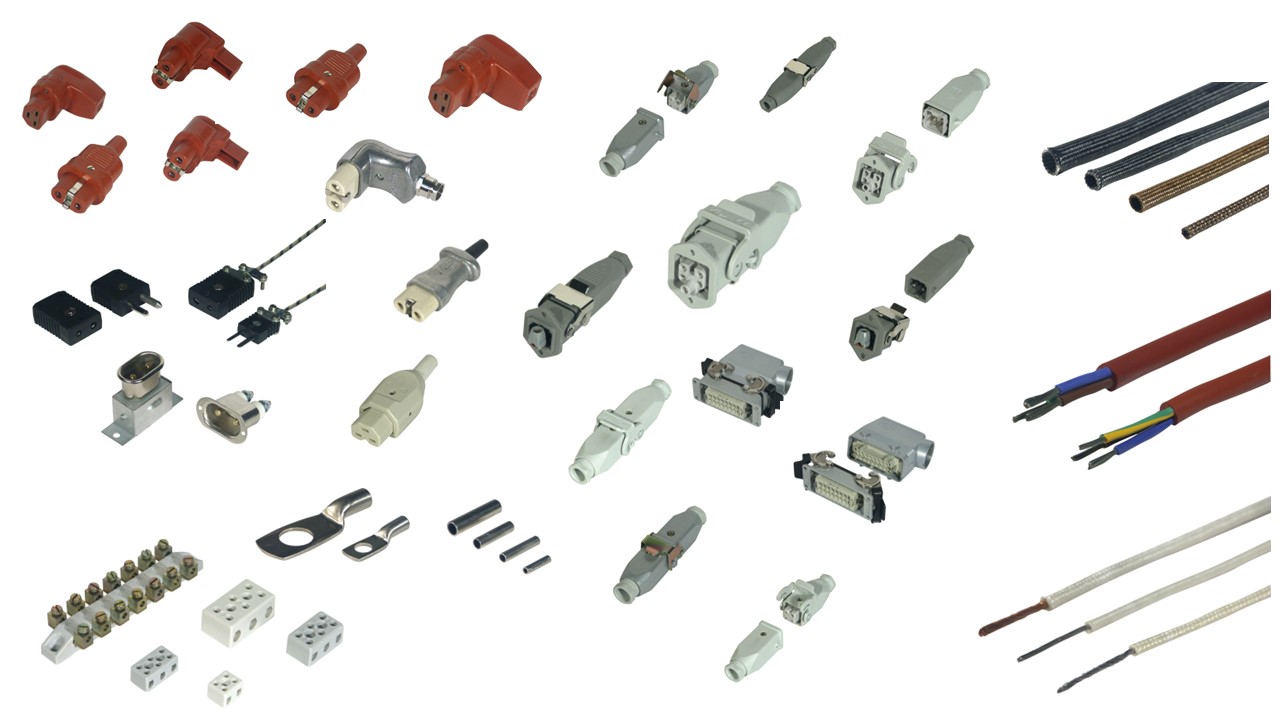

Additional Components

Explosion-proof level switch:

Horizontal or vertical mounting. Designed to ensure safe and reliable operation when monitoring immersion heaters used for liquid heating.

Thermal limiter – Type eB6:

Ensures safe temperature monitoring of the surface temperature of the immersion heater. Can be integrated into the power control and temperature regulation system.

Power and temperature control:

Whether a simple control box (on/off) or a thyristor-based cascade control panel is required, Electro-Therm provides the appropriate control system to match the heating function.

For any specific requirements, please contact us.

Typical Applications for ATEX Flanged Immersion Heaters for Gas or Air

- Motor anti-condensation heating

- Heaters for hot boxes or instrumentation cabinets

- Heating inserts for gas heaters (depending on the application, a flow monitor may be required to prevent the heater from overheating)

Typical Applications for ATEX Flanged Immersion Heaters for Liquids

- Lubrication systems for liquid heaters

- Thermal oil heaters

- Tanks containing water or process fluids

- Heat exchangers

To prevent overheating, liquid heaters must always remain covered by a sufficient liquid level.

ATEX-compliant flanged immersion heaters are used in the following sectors:

- Petrochemical, chemical, and pharmaceutical industries

- Oil and gas extraction, production, and distribution

- Mechanical engineering and plant construction

- Paint and coating industries

- Energy and environmental technologies

- Laboratory and analytical technologies

- Plastics and textile industries

- Packaging

- Industrial gases

This list is non-exhaustive.