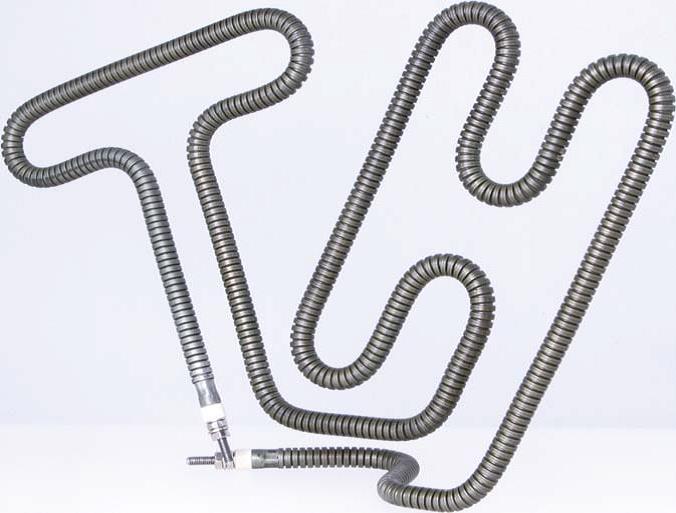

Elec-Flex - Flexible tubular heaters

Elec-Flex are robust tubular heater with excellent thermal properties, which can be freely shaped by hand.

Please contact us for any specific requirements.

Tubular heating elements with round and square cross-sections can be inserted into the mold by hand. The flexible outer jacket is adaptable to deformations and can be pressed against the surface of the groove, even in the absence of air inclusions, thus guaranteeing optimum heat transfer with high mechanical strength.

Technical possibilities and variants:

-Ø 6.5 Ø 8 and Ø 8.5 mm

-6X6 and 8X8 mm; high efficiency thanks to 75% contact surface in housing groove

-Max. length: 4000 mm

-Minimum bending radius for Ø 6.5 / 6X6 mm: 6.5mm

-Minimum bending radius for Ø 8 / Ø 8.5 / 8X8 mm: 10 mm

-Supply voltage: 230 V (standard)

-Connection: M2.5 Standard

Other connections and technical documentation on request. We can also manufacture those elements on demand.*

-To optimize the use of ELEC-FLEX, we recommend the use of a counter-plate to hold the coil in the tooling groove.

Material | Stainless steel |

|---|---|

Maximum surface temperature | 700°C |

Power tolerance | ± 10 % |

Length tolerance | ± 3 mm |

Elec-Flex or flexible tubular elements are mainly used for hot runners systems in the plastics industry. However, their flexibility enables us to offer them for many other industrial needs.

Please contact us for any specific requirements.

ELEC-FLEX are used in the following industries:

- Plastics and rubber industries

- O.E.M manufacturers

- Food industry

- Foundries (Zamak, etc.)

- Pharmaceuticals and chemicals

- Packaging

- Energy

This list is not exhaustive.