Cartridge heaters range

What are the advantages of electrical heating ?

Electrical heating is almost maintenance-free. Apart from a few periodic checks and inspections, no preventive maintenance is required.

Can the same heating elements be used for all kinds of applications?

No, electrical heating elements are often made for a specific application (e.g. water, air or oil). Although they may look similar, their structure is certainly different : Materials depend in part on the product to be heated, and the heat delivery, absorption and load are different depending on the application.

What are electrical heating elements used for ?

Electrical heating elements are often used for frost protection, process heating and space heating. These applications can be found in almost all industries, including packaging, food processing, plastics processing, petrochemicals, railways, etc.

Why choose Electro-Therm for your heating, temperature maintenance and thermal control needs ?

Electro-Therm is an ambitious company on a human scale, which has developed real expertise since its creation in 1972. Choosing Electro-Therm means benefiting from the expert, advice of a technical sales representative present in your area, who won't hesitate to visit you. Last but not least, working with Electro-Therm is the insurance of using available and quality products.

What is the maximum temperature you can reach with an electrical coil heater ?

Electrical coil heater can reach high temperature. Most of those elements can reach temperature of up to 300°C, but there are also products that easily reach temperature in excess of 1000°C.

How to heat, measure and control in an ATEX environment ?

Heating, measuring or regulating in ATEX environment requires specific products. That's why Electro-Therm's ATEX range is designed for use in potentially explosive environments. We can provide you with the solutions you need for use in the various types of ATEX zones (I, II, III...).

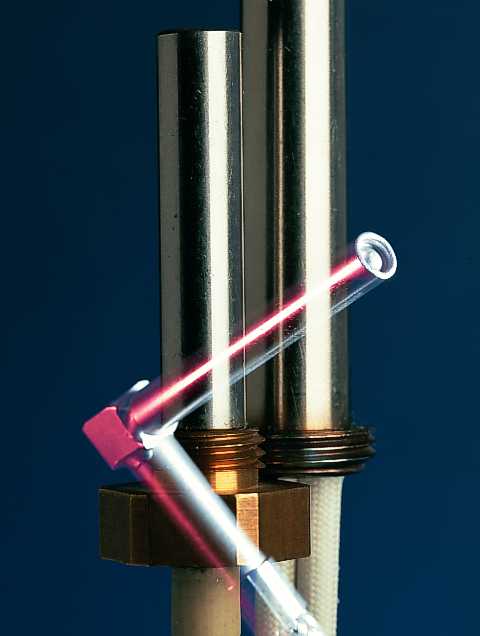

What is the function of a cartridge heater ?

A cartridge heater provides high-temperature heating of metal parts (molds, tools, etc.). Electro-Therm cartridge heaters are robust and versatile, and can operate in harsh environments (vibration, material jets, humidity, etc.). An ATEX range is also available.

How to use a cartridge heater optimally ?

To ensure the best possible performance, it's important to get the fit right. Fit is the difference between the nominal diameter of the heating element and the maximum diameter of the hole. Cartridges must therefore be placed in holes calibrated with a reamer. The entire cartridge must be in contact with the metal (i.e. no lack of metal in the bore), with only the ceramic head protruding.

What is the function of a formable coil heater ?

A formable coil heater provides high-temperature heating of metal parts (molds, tooling, etc.). Electro-Therm formable coil heaters are robust and versatile, and can operate in harsh environments (vibration, material jets, humidity...).

How do you form a coil heater ?

Formable coil heater can usually be bent by hand using a spindle. For heating cylinders, we recommend the use of a winding device.

In all cases, you should avoid excessively small rays and hammer blows. Caution ! Never straighten a shaped coil heater !

We can also form your heating elements to your requirements.

What is the function of a band heater ?

Usually, band heaters are used for all types of cylindrical heating and operate by contact. Applications are varied, thanks in particular to a wide selection of materials and dimensions, and an ATEX range is also available at Electro-Therm.

When should I use an aluminum-cast-in band heater ?

Usually, aluminum cast-in band heaters are particularly appropriate where moisture or condensation cannot be eliminated.

Aluminum cast-in band heaters are also available with ATEX certification.

Why use an industrial immersion heater ?

Usually, standard and customized immersion heaters are designed for heating liquids. They can be used to heat water, oil or even specific liquids, for which we will select the appropriate materials.

%20Cartouches%20chauffantes%20pr%C3%A9sentation%20.jpg)