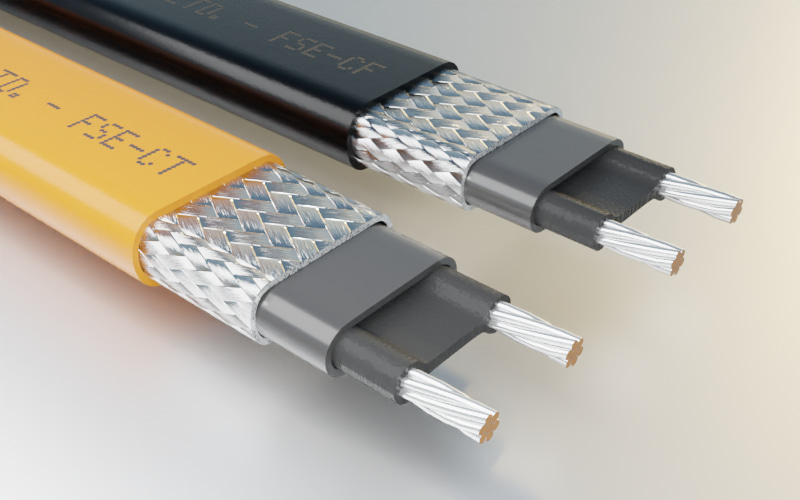

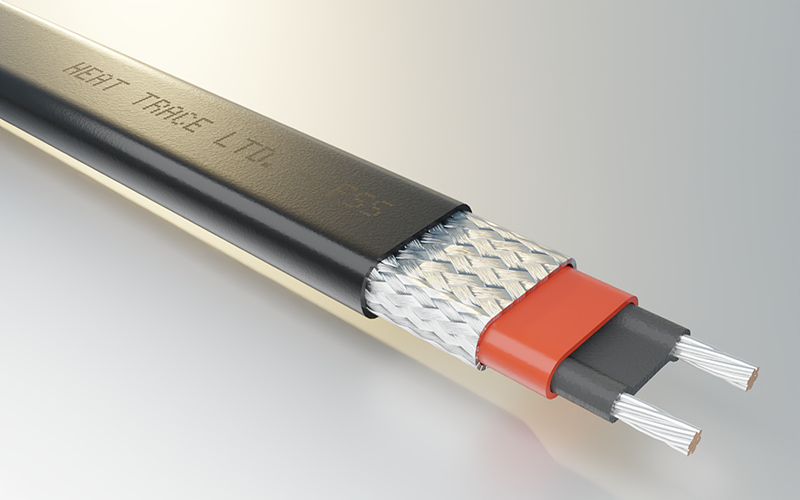

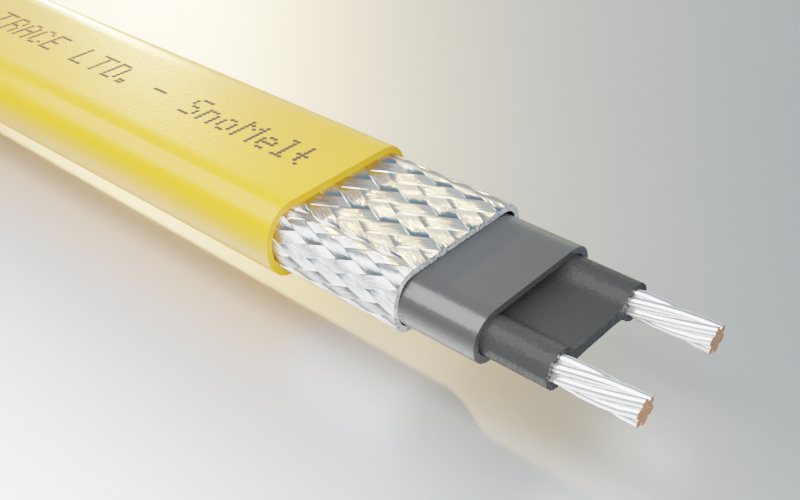

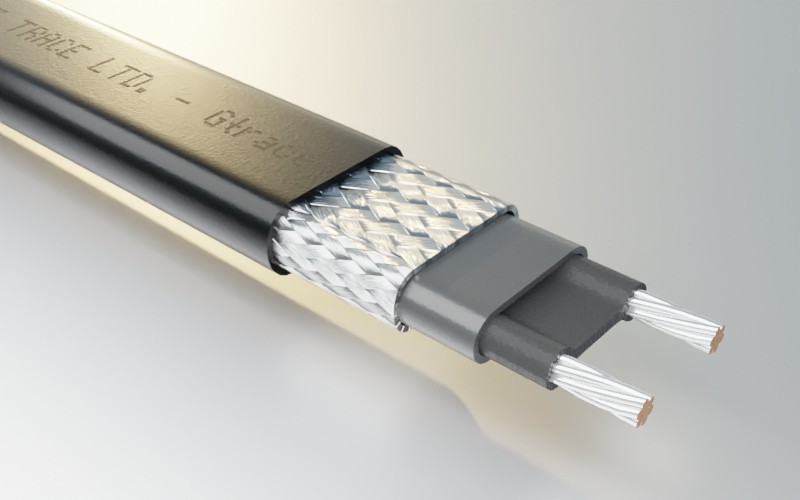

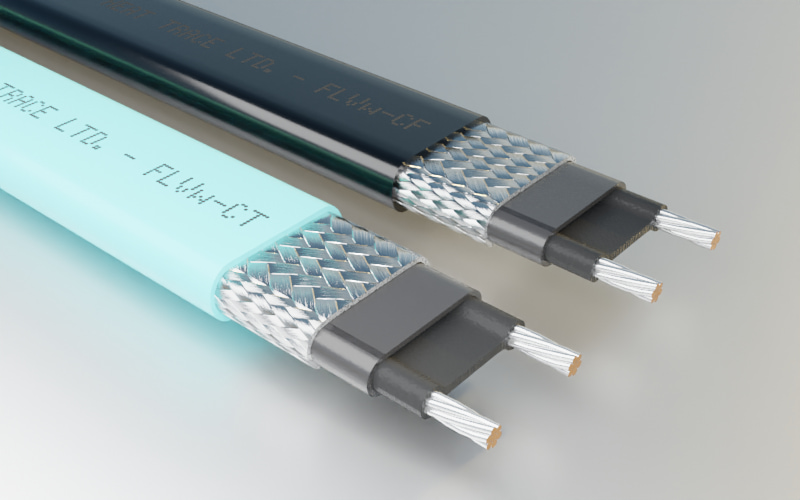

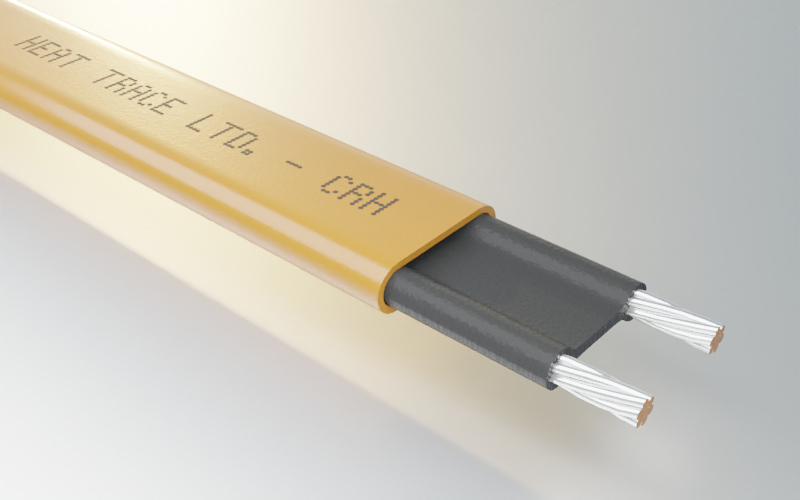

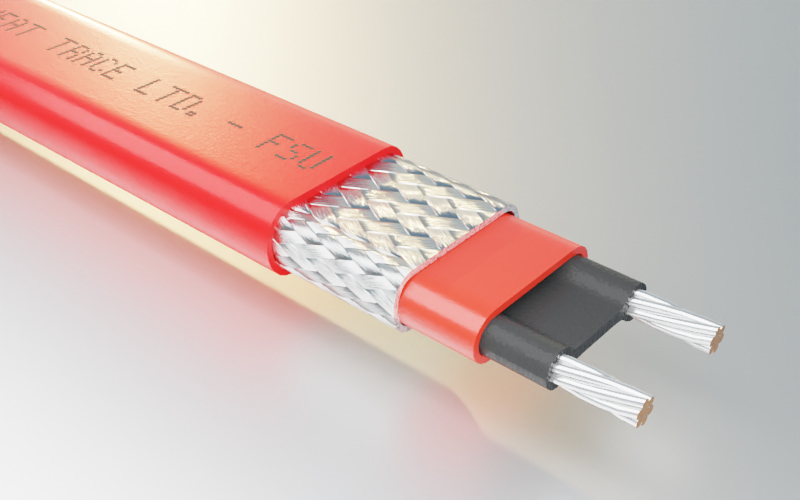

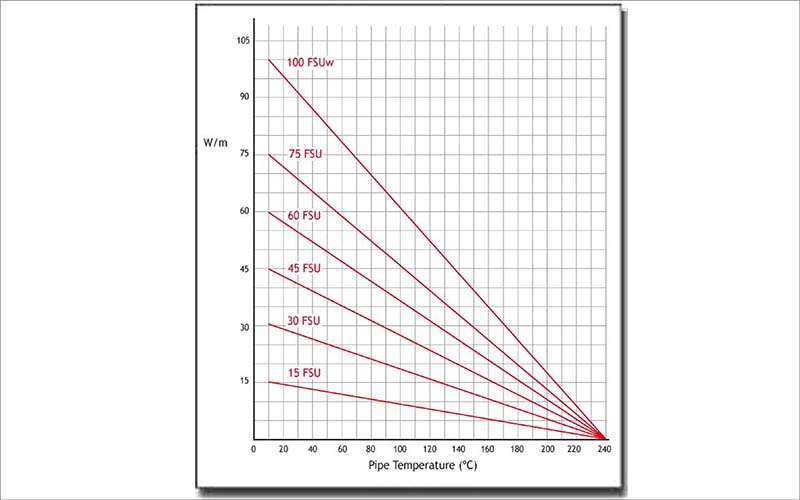

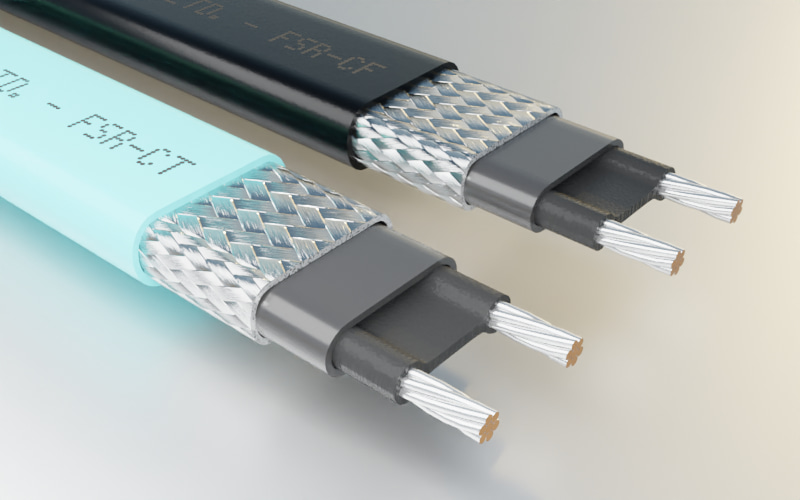

FSU/FSUw Self-Regulating Heating Cables – Tmax 250 °C

FSU and FSUw are self-regulating heating cables designed for freeze protection and temperature maintenance of pipes and vessels.

They provide maximum flexibility by being cut to length on site, adapting perfectly to installation layouts without the need for complex design calculations.

Thanks to their self-regulating technology, FSU cables automatically adjust their power output according to the surface temperature.

These heating cables will not overheat or burn out, even when overlapped.

The self-regulating heating cables are certified to DNV, ATEX, IEC, IECEx, and comply with European Union requirements, ensuring optimal safety and reliability in the most demanding environments.

For specific requirements, please contact us.

FSU and FSUw self-regulating heating cables provide safe and efficient thermal protection for temperature maintenance and freeze protection.

They are distinguished by their ease of installation, enhanced durability with a corrosion-resistant fluoropolymer outer jacket, and their ability to deliver up to 75 W/m at 10 °C.

FSU Cable Product Specifications – Maximum Allowable Exposure Temperature: 250 °C

Maximum Continuous Exposure (energized) | 250°C |

|---|---|

Maximum Allowable Exposure (de-energized) | 250°C |

Minimum Operating Temperature | -40ºC |

Temperature Classification | 15FSU - 60FSU T3 (200°C) 75FSU T2 (300°C) |

Power Supply | 12 - 277 V AC |

Cable Dimensions | FSU-NF 12.5 x 5.8mm +/- 0.5mm |

Minimum Installation Temperature | -40°C |

Minimum Bending Radius | FSU- NF - 35mm |

Weight (kg/100 m) | FSU-NF - 14.6 kg |

Maximum Protective Braid Resistance | 18.2 Ohm/km |

Cable Gland Thread | FSU-NF - M20 |

FSUw – The FSUw self-regulating heating cable ensures effective freeze protection and optimal temperature maintenance of pipes and vessels.

It combines intrinsic safety, simplified installation, and high performance up to 100 W/m, while withstanding temperatures of up to 250 °C.

Maximum Continuous Exposure Temperature (energized) | 250°C |

Maximum Allowable Exposure Temperature (de-energized) | 250°C |

Minimum Operating Temperature | -40ºC |

Temperature Classification | 100 FSUw T2 (300°C) |

Power Supply | 12 - 277 V AC |

Cable Dimensions | FSUw-NF 14.8 x 6.0mm +/- 0.5mm |

Minimum Installation Temperature | -40°C |

Minimum Bending Radius | FSUw-NF - 35mm |

Weight (kg/100 m) | FSUw-NF - 19.5 kg |

Maximum Protective Braid Resistance | 18.2 Ohm/km |

Cable Gland Thread | FSUw-NF - M25 |

FSU Heating Cables – Maximum Circuit Length (m) according to Breaker Ratings | ||||||

|---|---|---|---|---|---|---|

Reference | Start-up Temperature (°C) | 230V 10A | 16A | 20A | 32A | 50A |

15FSU | 10 | 76 | 122 | 154 | 172 | 172 |

0 | 70 | 112 | 140 | 172 | 172 | |

-20 | 62 | 98 | 122 | 172 | 172 | |

-40 | 52 | 82 | 102 | 164 | 172 | |

30FSU | 10 | 52 | 82 | 102 | 122 | 122 |

0 | 46 | 74 | 92 | 122 | 122 | |

-20 | 40 | 66 | 82 | 122 | 122 | |

-40 | 34 | 54 | 68 | 110 | 122 | |

45FSU | 10 | 38 | 62 | 76 | 100 | 100 |

0 | 34 | 56 | 70 | 100 | 100 | |

-20 | 30 | 50 | 62 | 98 | 100 | |

-40 | 22 | 34 | 44 | 70 | 100 | |

60FSU | 10 | 30 | 50 | 62 | 86 | 86 |

0 | 28 | 44 | 56 | 86 | 86 | |

-20 | 20 | 32 | 40 | 62 | 86 | |

-40 | 12 | 18 | 24 | 38 | 60 | |

75FSU | 10 | 22 | 34 | 44 | 70 | 76 |

0 | 16 | 26 | 34 | 54 | 76 | |

-20 | 12 | 18 | 24 | 38 | 60 | |

-40 | 8 | 12 | 14 | 22 | 36 | |

To be used with Type C circuit breakers in accordance with IEC EN 60898 | ||||||

FSUw – Maximum Circuit Length (m) according to Breaker Ratings

Reference | Start-up Temperature (°C) | 230v 10A | 16A | 20A | 32A | 50A |

100FSUw | 10 | 18 | 30 | 36 | 58 | 84 |

0 | 18 | 28 | 34 | 56 | 84 | |

-20 | 16 | 24 | 30 | 50 | 76 | |

-40 | 14 | 22 | 28 | 46 | 70 | |

To be used with Type C circuit breakers in accordance with IEC EN 60898.* | ||||||

In cold environments, ensuring the continuity of industrial operations requires effective freeze protection.

Application Example:

In industrial environments and cold climates, water, chemical pipelines, and storage tanks must be protected against freezing in order to ensure service continuity and process safety.

Problem Example:

Thermal insulation alone is insufficient. For example, a 25 mm diameter water pipe at 5 °C, insulated with 25 mm of insulation, will reach freezing point in less than one hour if the ambient temperature is –10 °C. Using 150 °C steam is not a suitable alternative for simple freeze protection, especially as condensate return lines themselves are at risk of freezing.

Solution:

The most reliable and effective approach is the use of low-power electric heating cables.

FSU and FSUw self-regulating heating cables are specifically designed for:

-Freeze protection of pipelines and vessels

-Accurate process temperature maintenance in industrial applications

Finally, it should be noted that the choice of control system has a direct impact on operating costs: optimized control helps reduce energy consumption while ensuring installation safety.

Self-Regulating Heating Cables – FSU/FSUw are used in the following sectors:

-Water Treatment and Technical Installations

-Industrial Buildings and Outdoor Installations

-Construction

-Food & Beverage Industry

-Pharmaceutical Industry

-Chemical & Petrochemical

-General Industry

This list is not exhaustive.

.jpg)